A typical Switched Mode Power Supply comprises a front-end AC-DC rectifier, generating an unregulated DC input voltage for the switching circuit. A high-frequency PWM (Pulse Width Modulation) drive transforms this DC output into a pulsating square wave through a MOSFET/IGBT switching device. A high-frequency transformer then isolates, steps down, and converts this square wave DC into square wave AC output. Finally, the output is rectified and filtered to produce a smooth, ripple-free regulated DC output. Closed-loop feedback control ensures precise output regulation, intrinsic protection against overload and short circuit.

Advantages of SMPS Battery Chargers

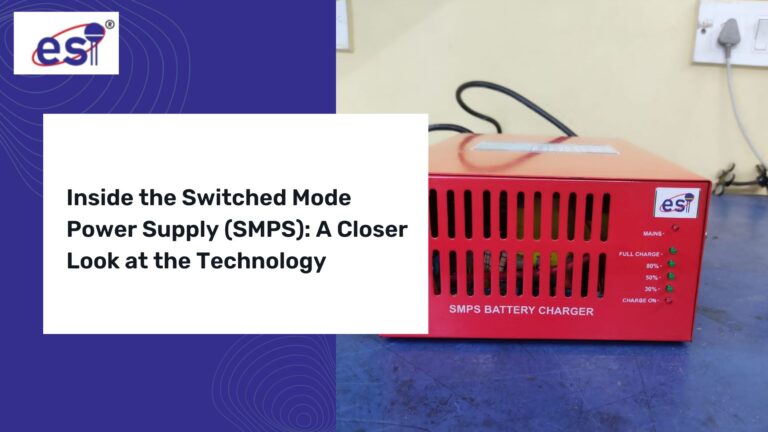

ESI SMPS Battery Chargers bring several advantages to the table:

- Cost Efficiency: At least 40% lower in cost compared to conventional thyristor/transistor-based or manual battery chargers.

- Higher Efficiency: Ensures maximum power transfer with minimal losses.

- Compact and Light: The design is space-saving and lightweight, making installation and handling easier.

- Easy Servicing: Maintenance and servicing are simplified through PCB replacement.

ESI SMPS Battery Charger Product Range and Applications

ESI has successfully designed, manufactured, and supplied SMPS-based Battery Chargers for various applications, including:

- DG set Battery Charger

- VCB panel Battery Charger

- Battery Charger for firefighting panels

- Panel mounting 12V & 24V Battery Chargers for control panels

- Variable current Battery Chargers for battery service centers

- 48V & 60V E-rickshaw Battery Chargers

- Battery Chargers for traction batteries from 24V to 110V

- 30V, 36V, 48V & 110V Battery Chargers for substations

With ESI’s commitment to quality and innovation, their SMPS Battery Chargers stand as a reliable solution for diverse industrial applications, ensuring the longevity and optimal performance of batteries across the board.