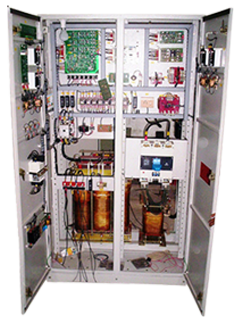

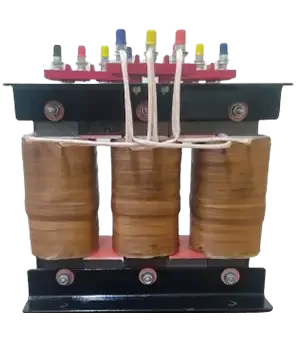

Electro Service India – An ISO 9001:2015 MSME unit, is a leading manufacturer of Battery Charger, Float Charger, SMPS Charger, SMPS Power Supply, Control Transformer, AC Heater control panels, AC & DC Distribution Board.

ESI started its operation with manufacturing of LT Transformers and Chokes for industrial applications in 1987. Within a very short period ESI has earned the unflinching patronage of discerning users which include Giant Steel Plants, Electricity Boards, Large Public Sectors, Multinationals, National Laboratories and a number of quality conscious Medium & Small Industries.

We take great pride in delivering quality products and services to our clients. Here are some testimonials from our valued customers:

For any inquiries or assistance, kindly complete the form below. We appreciate the opportunity to assist you promptly and professionally.

Bank Name: AXIS BANK LTD.

Bank A/C No : 920020051291735

IFSC Code: UTIB0000034

GSTN: 19AADFE1779R2ZM

Copyright 2024 Electro Service India, All rights reserved | Designed by LNSEL